Business Field

Medical Diagnosis

The Optical Coherence Tomography (OCT) device for medical diagnosis is a high-resolution imaging technology based on near-infrared light, which is mainly used for non-invasive and radiation-free in vivo tissue tomography. By detecting light reflection signals, it generates cross-sectional images with micron-level resolution. Widely applied in ophthalmology, dermatology and other fields, it enables real-time observation of tissue microstructure and assists in the early diagnosis of diseases.

Industrial Inspection

The Optical Coherence Tomography (OCT) device for industrial inspection is specially designed for the non-destructive testing of the internal microstructure of materials or components. By emitting low-coherence light beams and analyzing the reflected signals, it can generate real-time cross-sectional or three-dimensional images of samples with micron-level resolution. It is suitable for the internal defect detection, layer thickness measurement and quality control of transparent/translucent materials or precision components.

OCT Accessories

Our company has developed a variety of OCT accessories, including variable optical delay line, motorized fiber polarization controllers, OCT for laser weld measurement, OCT spectrometer series etc. With innovative R&D, these accessories meet the efficiency requirements of enterprises. They feature high precision, anti-interference performance, high repeatability, and fast response, and are suitable for continuous detection in industrial sites and harsh environments.

Hot-selling Products

Ophthalmic OCT

- Fully automatic robotic scan

- Ultra-fast A-scan rate: 400,000 A-scan per second

High-clarity OCTA blood-flow imaging

Dermatologic OCT

- Enables viable “optical biopsy”

- Suitable for a variety of skin conditions

- Provides more vascular network information

SS/SD OCT Systems

- Customizable System Paramters

- Real-time En Face Visualization

- Optimal for Non-destructive Testing

- In-situ Laster Welding Monitoring

Variable Optical Delay Line

- Wavelength: 840 nm-1310nm

- Optical delay time: 670 ps/ 1470 ps/ 2000 ps/4000 ps

- Minimum delay variation: 33 fs/ 0.67 fs

OCT for Laser Weld Measurement

- In-situ real-time quality monitoring

- Significantly improve production efficiency

- Continuous monitoring throughout the welding process

OCT Spectrometer Series

- Multiple models available

- Ultra-high sensitivity and signal-to-noise ratio

- High-quality OCT/OCTA in vivo biological imaging

Motorized Fiber Polarization Controllers

- Conversion between linear, circular and el-liptical polarization state

- Motorized paddle rotation:2 paddle version and 3 paddle version

OCT Scanner

- Flat image plane

- Large field of view

- Low F-Theta distortion

- Ideal for DIY OCT or confocal systems

Principles of OCT Technology

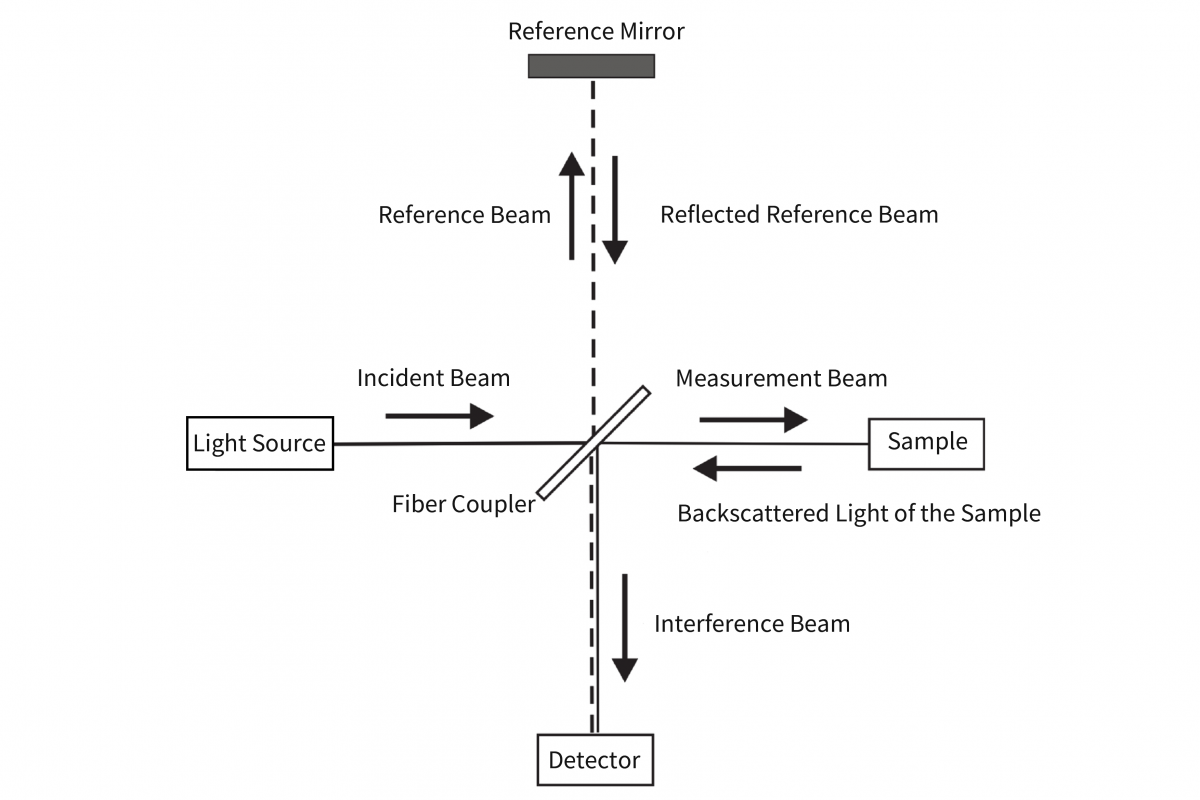

OCT leverages the principle of optical low-coherence interferometry. It splits the light emitted by a broadband light source into two beams: one beam irradiates the measured object (sample light), which undergoes backscattering after entering the object. The other beam acts as reference light, which is reflected back by a fixed reference mirror. The two beams recombine at the beam splitter to generate an interference signal. An effective interference signal is only formed when the optical path difference between the two arms falls within the coherence length of the light source. By measuring the variation of the interference signal with the optical path difference, information about different depths inside the sample can be obtained, and then a 2D or 3D structural image of the sample can be reconstructed.

Learn More

-SS-OCT System Configuration

-SD-OCT System Configuration

-Exhibition Updates

-Company News

-About Us & Corporate Culture

-Corporate Honors & Partners

-Contact Information

-Company Address