OCT for Laser Weld Measurement

OCT for Laser Weld Measurement

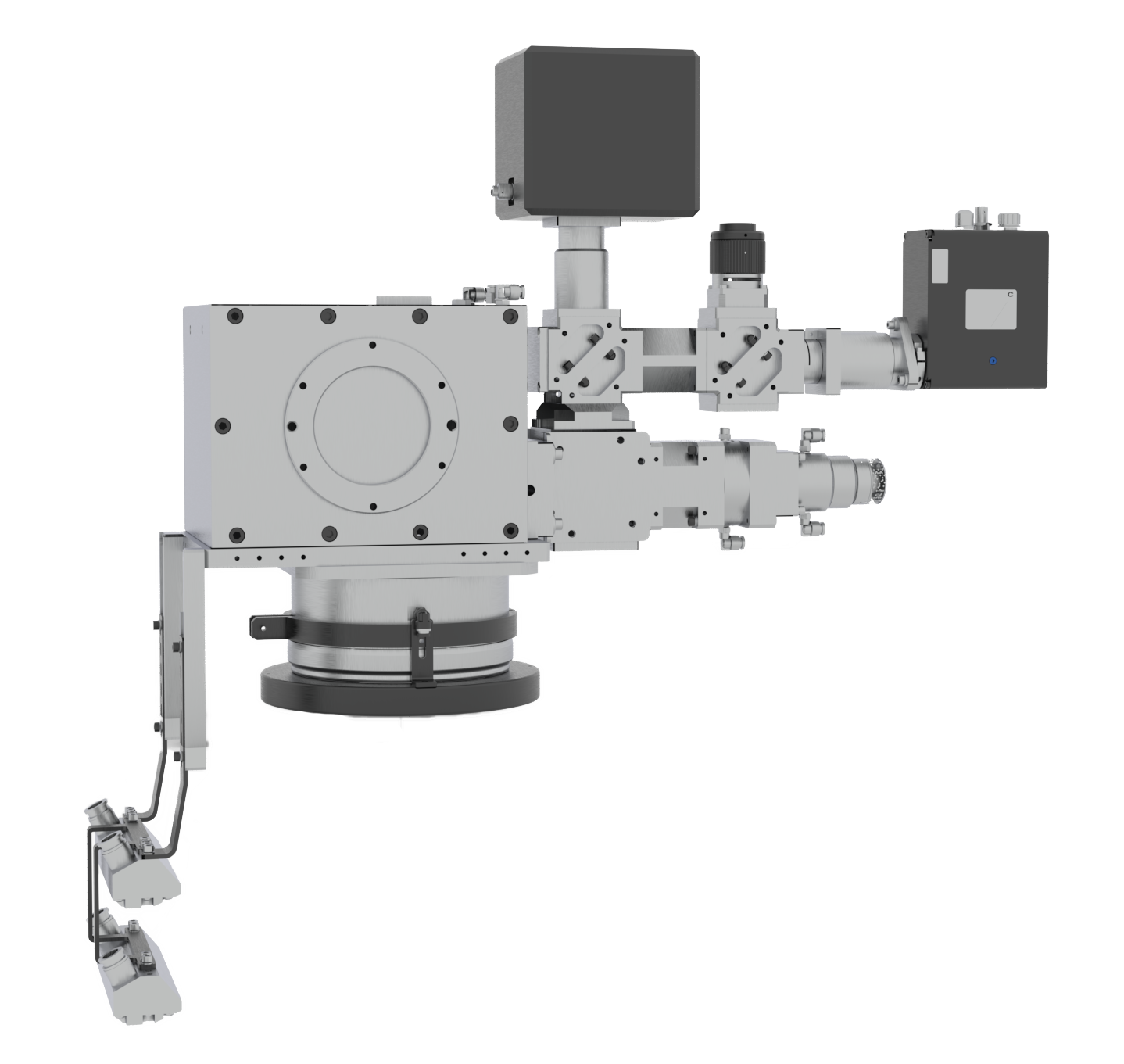

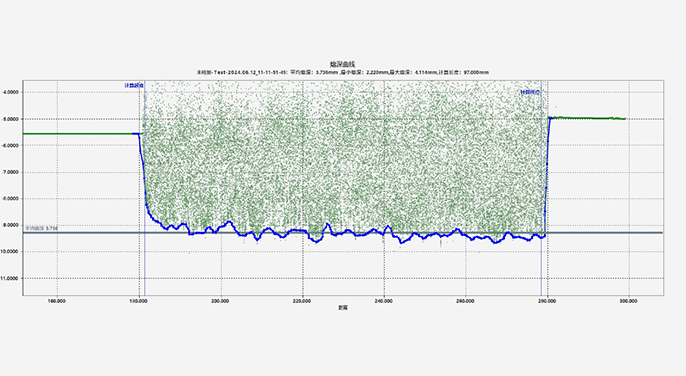

The OCT galvanometer welding penetration detection system realizes online real-time detection of laser welding penetration for various metal materials such as copper, aluminum and steel based on the high-precision laser low-coherence measurement principle. It accurately calculates the weld keyhole depth to achieve real-time penetration measurement and integrate welding with penetration detection. Its components include the OCT basic optical module, data acquisition and processing module, spectrometer module and welding optical path module.

Product Features

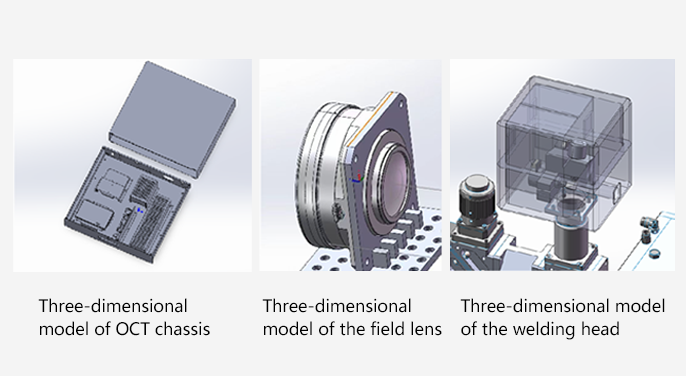

Independently Designed Optical Components and Optical Systems

Basic Optical Module: SLD Light Source, Optical Fiber Assemblies, Motorized Reference Arm Assemblies, Welding Galvanometer Scanning Module

Ultra-low Loss Optical Fiber Components for Higher Energy Utilization Efficiency

Strong Anti-interference Capability Against Laser Welding

High Measurement Stability

Welding Optical Path Module

Fully independently designed and developed with customizable functions supported.

The welding laser and OCT laser optical paths are coaxial.

The underlying control technology and self-developed algorithms enable precise beam control for high-precision detection.

An accurate mathematical model of welding parameters and penetration depth can be established.

It provides a reliable data foundation for the welding big data analysis system.

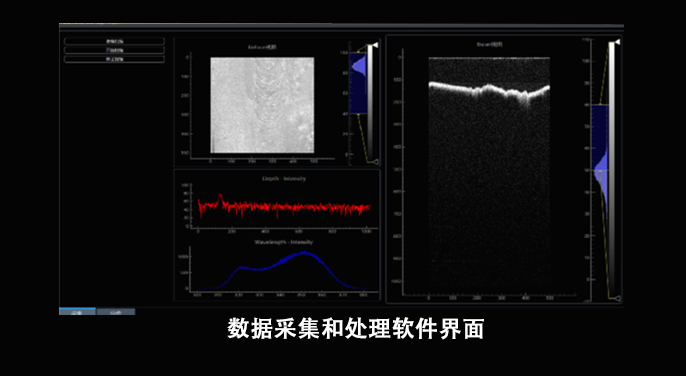

Data Acquisition and Processing

Supports customized requirements for specific scenarios.

Self-developed welding software and OCT inspection software can be rapidly optimized and adjusted adaptively according to the needs of users’ production lines.

Simple and easy to use, safe and reliable.

Self-developed Spectrometer

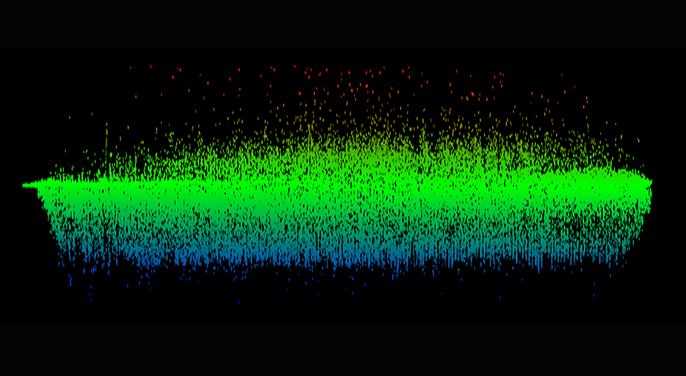

It features 3D tomographic imaging capability with high resolution, high signal-to-noise ratio and large imaging depth.

Independent optical design scheme: high-efficiency VPH grating with optical resolution close to the diffraction limit.

Universal camera link interfaces: Camera Link, USB camera.

Excellent roll-off performance and ultra-high sensitivity.

OCT Technology Online Monitoring Solution

Enables non-contact real-time detection

Ensures welding quality stability

Significantly improves production efficiency

Ideal for welding quality control of lightweight materials

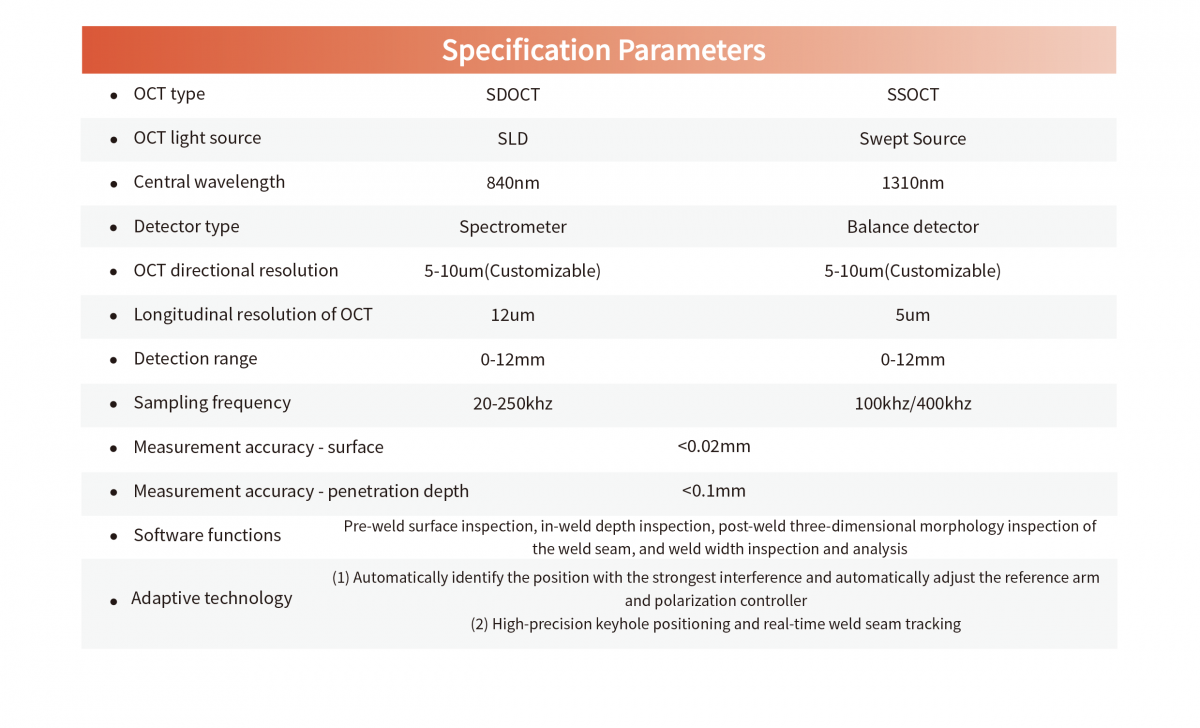

Specification Parameters